Textile Filter Testing Shows Promise for Carbon Capture

North Carolina State University researchers found they could filter carbon dioxide from air and gas mixtures at promising rates using a proposed new textile-based filter that combines cotton fabric and an enzyme called carbonic anhydrase – one of nature’s tools for speeding chemical reactions.

The findings from initial laboratory testing represent a step forward in the development of a possible new carbon capture technology that could reduce carbon dioxide emissions from biomass, coal or natural gas power plants. And while the filter would need to be scaled up in size significantly, the researchers think their design would make that step easier compared with other proposed solutions.

“With this technology, we want to stop carbon dioxide emissions at the source, and power plants are the main source of carbon dioxide emissions right now,” said the study’s lead author Jialong Shen, postdoctoral research scholar at NC State. “We think the main advantage of our method compared to similarly targeted research is that our method could be easily scaled up using traditional textile manufacturing facilities.”

The centerpiece of the research team’s design for a proposed textile-based chemical filter is the naturally occurring enzyme carbonic anhydrase, which can speed a reaction in which carbon dioxide and water will turn into bicarbonate, a compound in baking soda. The enzyme plays an important role in the human body; it helps transport carbon dioxide so it can be exhaled.

“We borrowed this wonderful enzyme in our process to speed up the carbon dioxide uptake in an aqueous solution,” Shen said.

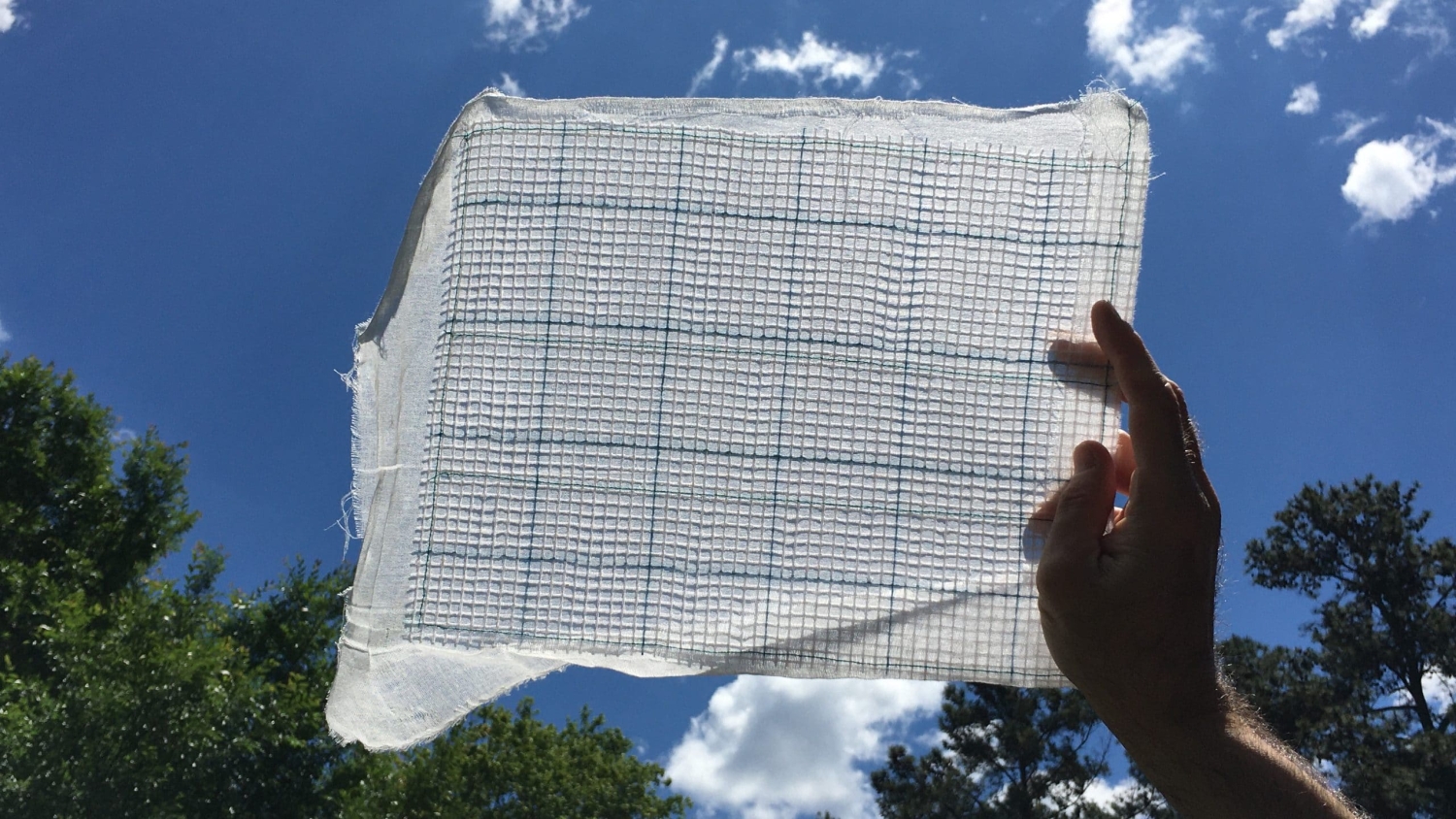

To create the filter, researchers attached the enzyme to a two-layer cotton fabric by dunking the fabric in a solution containing a material called chitosan, which acts like a glue. The chitosan physically traps the enzyme, causing it to stick to the fabric.

The researchers then ran a series of experiments to see how well their filter would separate carbon dioxide from an air mixture of carbon dioxide and nitrogen, simulating levels emitted by power plants. They rolled the fabric into a spiral so that it can be shoved into a tube. They pushed the gas through the tube, along with a water-based solution. As the carbon dioxide reacted with the water in the solution and the enzyme, it turned into bicarbonate and dripped down the filter and the tube. Then, they captured the bicarbonate solution and routed it out.

When they pushed air through the filter at a rate of 4 liters per minute, they could pull out 52.3% of carbon dioxide with a single-stacked filter, and 81.7% with a double-stacked filter. While the findings are promising, they need to test the filter against the faster air flow rates that are used in commercial power plants. For comparison, a full-scale operation would need to process more than 10 million liters of flue gas per minute. The researchers are working with collaborators to test at a bigger scale and to compare their technology to other comparable technologies under study.

“It’s a story still in progress, but we got some really exciting initial results,” said study co-author Sonja Salmon, associate professor of textile engineering, chemistry and science at NC State. “We’ve made very significant progress.”

In addition to testing the filters’ carbon capture rates, they also tested how well the filter would work after five cycles of washing, drying and storing. They found it could maintain a high level of performance.

“The enzyme can be maintained at a lower temperature for a very long time and it’s going to be durable,” Shen said. “The fabric provides physical support and structure for it, while providing a large surface area for it to react with the carbon dioxide.”

Capturing the carbon dioxide is just one part of the process – they also are working on the problem of how to recycle the liquid after it exits the filter, as well as the process of turning the bicarbonate back into carbon dioxide so it can be stored and disposed of, or used for other commercial purposes.

“We want to regenerate the water solution we use with the filter so we can use it over and over,” Salmon said. “That side of the process needs more work, to make the regeneration energy of the solvent as low as possible.”

The researchers say new technologies for carbon capture are needed that would require less energy than existing commercialized carbon capture technologies, some of which are used only to filter carbon dioxide and release it back into the atmosphere. They hope their carbon capture system could help drive down the cost to help boost adoption.

“There are a lot of different ways to capture carbon dioxide,” Shen said. “The current standard in the commercial setting uses a reaction that is so fast, so robust, and that binds the carbon dioxide so well, that you can’t easily get the carbon dioxide out. You have to use very high temperatures, which means a lot of energy consumption. That makes your process more expensive.”

The study, “Carbonic Anhydrase Immobilized on Textile Structured Packing Using Chitosan Entrapment for CO2 Capture” was published online in ACS Sustainable Chemistry & Engineering. Co-authors included Yue Yuan, who completed her Ph.D. on Salmon’s team. The study was supported by NC State and by the Alliance for Sustainable Energy, managing and operator contractor for the National Renewable Energy Laboratory (NREL) for the U.S. Department of Energy, through a Bioenergy Technologies Office (BETO)-funded project, as a collaboration between NREL, NC State and the University of Kentucky’s Center for Applied Energy Research, using enzymes from Novozymes.

-oleniacz-

Note to editors: The abstract follows.

“Carbonic Anhydrase Immobilized on Textile Structured Packing Using Chitosan Entrapment for CO2 Capture”

Authors: Jialong Shen, Yue Yuan and Sonja Salmon.

Published in ACS Sustainable Chemistry & Engineering on June 1, 2022.

DOI: 10.1021/acssuschemeng.2c02545

Abstract: Innovative carbon dioxide (CO2) capture approaches are urgently needed to lower and reverse CO2 emissions that lead to climate change. Here we report the design, fabrication and testing of high efficiency biocatalytic textile-based gas-liquid contactors made using versatile, sustainable and readily available polymers, cellulose and chitosan, together with immobilized carbonic anhydrase (CA) enzyme to accelerate CO2 absorption into benign, low-energy, aqueous potassium carbonate (K2CO3)-based solvents. This novel structured packing is able to withstand the CO2 scrubbing environment, will be simple to scale up, and will be useful as a “drop-in” for conventional chemical absorption systems as well as offer new possibilities for direct air capture. Immobilizing CA in a thin coating on textile packing surfaces minimizes the enzyme requirement, retains enzyme in the absorber for high catalytic benefit and longevity with repeated use, and allows downstream process flexibility by preventing CA from traveling to other unit operations, e.g. high temperature desorption where enzyme could become inactivated. CA immobilization on cotton fiber textile packing materials by entrapment with chitosan exhibited an activity recovery of at least 49% and activity retentions of higher than 68% after 10 repeated wash and retest cycles over 5 days and up to 41% after 31-day incubation in 10% K2CO3 at 40 ℃. The lightweight biocatalytic textile packing modules are sturdy and easily handled with no sharp edges or dusting issues as can accompany conventional metal packing or particulate immobilized enzymes. In laboratory scale countercurrent CO2 absorption tests at 4 liters per minute total gas flow rates, CA immobilized textile packings delivered average CO2 absorption efficiencies of 52.3% and 81.7%, for single and double-stacked packings, respectively, versus 26.6% and 46.4% for single and double-stacked no-enzyme control textile packings, and versus 3.6% for conventional glass Raschig rings filled to the equivalent single-stacked packing height. Textile packings exhibited excellent solvent distribution throughout the packing even at low liquid flow rates, maintaining uniform gas contact with the wetted solid contacting surfaces across a range of different liquid flow rates, leading to robust CO2 capture efficiency. Biocatalytic textile packing retained 66% of the initial CO2 capture performance after 5 cycles of washing, drying, ambient storage and retesting over a period of 66 days. In a separate test with freshly made packing, 76.5% performance retention was observed after a continuous 120-hour recirculation longevity test.

This post was originally published in NC State News.