Intellectual property resulting from research at NC State indicates an innovation culture that often transcends discliplines: our research portfolio and technology pipeline is a convergence of the best research from our colleges, institutes, and collaborations. From dwarf butterfly bushes to porphyrin compunds, NC State's research range is comprehensive.

In FY2009, NC State researchers submitted 130 intellectual property disclosures, describing a vast range of proprietary technologies, methods, formulas, and plant varieties.

In this article, we take a closer look at what NC State researchers developed during the past year.

Nanofibers as a Responsive Fabric for Drug Delivery (File 09-055) (from the College of Agriculture and Life Sciences/College of Textiles/College of Engineering) ::::

Nanofibers as a Responsive Fabric for Drug Delivery (File 09-055) (from the College of Agriculture and Life Sciences/College of Textiles/College of Engineering) ::::

Drug encapsulation in biodegradable polymers is known to yield controlled release functionality in drug delivery. As an improvement of this commercial application, research is underway to determine the feasibility of using plant virus capsids as carriers of therapeutics. This invention, developed by researchers at North Carolina State University, introduced a unique material system to impregnate a biodegradable nonwoven nanofiber polymer with a novel plant virus, as carrier, which is loaded with drug. This unique structure utilizes the two different kinetic regimes of polymer and drug release from the virus to control more precisely the rate of drug release to patients.

In addition to drug delivery, such devices could be used to generate a whole new class of diagnostic or sensing systems to be used to detect early stages of disease, or low levels of toxins, other viruses, bacteria, etc. Specific technology advantages include the control of delivery of drugs over time or the delivery can occur instantly if required. The release of drug from the virus is likely to result in a more uniform release over time compared to the drug released from a polymer, and dependent on the attributes of the polymer used, this device could have a wide range of applications in diagnostic or sensing systems.

Process Heated Torrefaction Machine (PHTM) (File 09-103) (from the College of Natural Resources) ::::

Process Heated Torrefaction Machine (PHTM) (File 09-103) (from the College of Natural Resources) ::::

Combustion of coal produces pollutants such as sulfur dioxide (SO2), nitrogen oxide (NOx), particulate matter, and carbon monoxide. The Clean Air Act Amendments of 1990 (CAAA) instituted a cap and trade program that requires power plants to meet certain targets for SO2 and NOx emissions.

Research from the College of Natural Resources is looking to lighten that burden by creating energy from woodchips. NC State researchers have engineered a proprietary machine called a “torrefier” that turns biomass into "CarolinaCoal." There are no current torrefaction technology implementations that are field portable and self heated. NC State's invention is both! Significant advantages of NC State's invention are 1) the mobility of the process which lends itself to field based operations (reducing transportation costs) and; 2) the machine is largely self-powered producing a large energy return.

Woodchips go into a large funnel at the top of the machine and come out as hard, dry, black "energy pellets" at the bottom. In the process, the woodchips are physically and chemically altered – through heat and pressure – to make them denser, drier and easier to crush. The pellets are lighter than woodchips but retain 90 percent of their original energy content. That makes them an ideal feedstock for electric power plants that traditionally use coal to generate energy for businesses and residential neighborhoods.

Smart Delivery of Radioactive Microspheres for Cancer Therapy (File 09-056) (from the College of Engineering) ::::

Smart Delivery of Radioactive Microspheres for Cancer Therapy (File 09-056) (from the College of Engineering) ::::

Currently, there is no way to ensure targeted delivery of microspheres specifically to tumor cells while sparing the healthy tissue and other body organs. As a result, a certain portion of injected microspheres end up depositing away from the tumor and destroying healthy liver tissue and may affect other parts of the patient's body as well.

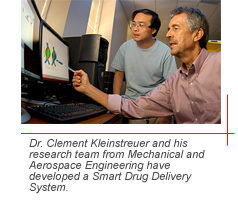

Professor Clement Kleinstreuer and his research team from the Department of

Mechanical and Aerospace Engineering

have developed a novel technique for ensuring targeted delivery of potentially all microspheres directly to single or multiple tumors. This project is being conducted in collaboration with Dr. Andy Kennedy of Wake Radiology Oncology in Cary, NC. Using computer simulations of patient-specific particle-hemodynamics, the optimal release position of the microspheres can be determined by a computational backtracking method. The accuracy of the computer simulation model has been validated by comparison with experimental flow data from patients. Implementation of the optimal "drug" targeting methodology is being accomplished with a novel smart micro-catheter (SMC). Modifications to the present SMC designs, reflecting various levels of sophistication and hence different cost factors are currently under development.

Professor Clement Kleinstreuer and his research team from the Department of

Mechanical and Aerospace Engineering

have developed a novel technique for ensuring targeted delivery of potentially all microspheres directly to single or multiple tumors. This project is being conducted in collaboration with Dr. Andy Kennedy of Wake Radiology Oncology in Cary, NC. Using computer simulations of patient-specific particle-hemodynamics, the optimal release position of the microspheres can be determined by a computational backtracking method. The accuracy of the computer simulation model has been validated by comparison with experimental flow data from patients. Implementation of the optimal "drug" targeting methodology is being accomplished with a novel smart micro-catheter (SMC). Modifications to the present SMC designs, reflecting various levels of sophistication and hence different cost factors are currently under development.

Advantages of Dr. Keinstreuer's technology over currently used methods include reduced side-effects of radioembolization therapy; optimal drug delivery, resulting in improved efficacy of the therapy, the potential to lower the cost of therapy by reducing the required dose to achieve optimal effects on tumors; and the technology's adaptability for effective drug delivery to any tumor.