Researchers Create New E-Textiles with Fiber-Level Sensors

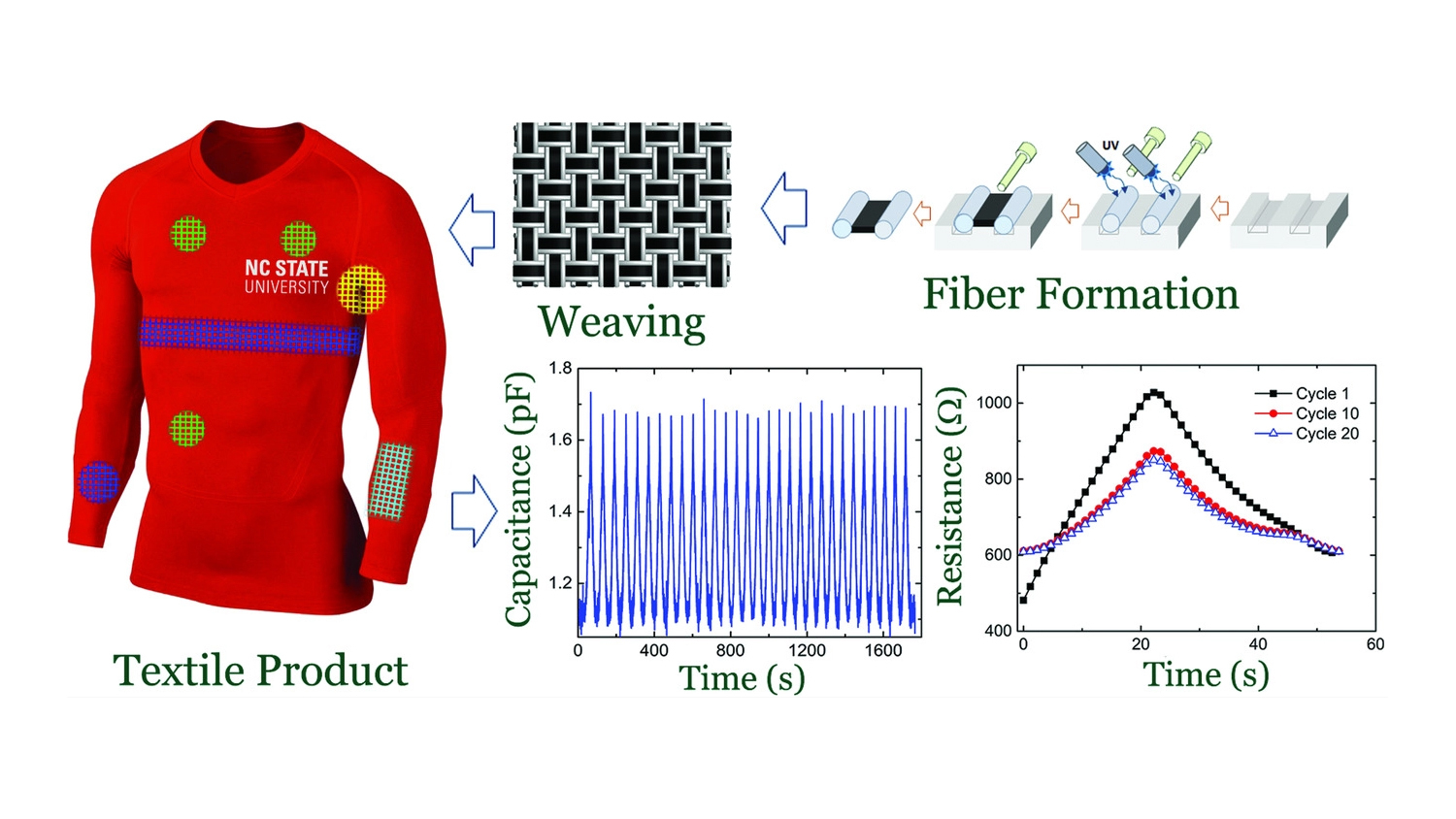

Next-generation electronic textiles that incorporate sensors into smart garments at the fiber level could help streamline the electronic textile manufacturing process.

North Carolina State University textiles experts and electrical engineers have teamed up to create a new sensor array within the fabric structure that’s capable of detecting pressure, stretching, shearing and wetness.

The multimodal and multifunctional sensor assembly could be used for a range of e-textile applications such as monitoring soldiers in combat, preventing bedsores in patients, helping high-performance athletes reach their ideal training heart rate and detecting when infants’ diapers are wet, says Ashish Kapoor, lead author of a journal article about the research and a Ph.D. student in NC State’s Fiber and Polymer Science Program.

The fiber design could be used to create sensor arrays of textile elements, or texels, that detect several measurable elements at once.

“Integrating the electrical functionality at the fiber level means it is not going to compromise the textile’s basic properties like flexibility and conformability,” Kapoor says. “With a fiber design that is multimodal in nature, a single sensing structure is capable of sensing more than one type of parameter, as well as the presence of any kind of wetness. We’re using these fiber sensors to monitor the prosthetic socket environment of amputees, which is an area which has very high pressure and temperature under wetness levels.”

Another important advantage of the design is that the fibers can be manufactured using standard roll-to-roll textile processing technologies, allowing low cost production of flexible sensor systems that can cover large areas.

“They can be also used to make smart carpets or other touch-sensitive textiles,” Kapoor says. “You can put them into automotive car seats sensors. They have a variety of uses, so we have tried to focus on getting the functionality so that if you think that you need a flexible sensor, this can be the solution.”

The research appears in Advanced Materials Technologies.

Co-authors are Michael McKnight, Talha Agcayazi, Hannah Kausche and Alper Bozkurt, all with NC State’s Department of Electrical and Computer Engineering; and corresponding author T.K. Ghosh and Kony Chatterjee with NC State’s Fiber and Polymer Science Program.

– ford –

Note to editors: An abstract of the work follows.

“Toward Fully-Manufacturable Fiber Assembly based Concurrent Multimodal and Multifunctional Sensors for E-textiles”

DOI: 10.1002/admt.201800281

Authors: Ashish Kapoor, Michael McKnight, Kony Chatterjee, Talha Agcayazi, HannahKausche, Alper Bozkurt and Tushar K. Ghosh, all with North Carolina State University

Published: Oct, 11, 2018 in Advanced Materials Technologies

Abstract: Soft polymer-based sensors as an integral part of textile structures have attracted considerable scientific and commercial interest recently because of their potential used in healthcare, security systems and other areas. While electronic sensing functionalities can be incorporated into textiles at one or more of the hierarchical levels of molecules, fibers, yarns, or fabrics, arguably a more practical and inconspicuous means to introduce the desired electrical characteristics is at the fiber level, using processes that are compatible to textiles. Here, we report a multimodal and multifunctional sensor array formed within a woven fabric structure using bicomponent fibers with ordered insulating and conducting segments. We successfully demonstrate the multifunctional characteristics of the sensors by measuring tactile, tensile, and shear deformations, as well as wetness and biopotential. While the unobtrusive integration of sensing capabilities offer possibilities to preserve all desirable textile qualities, our fiber-based approach demonstrates the potential for scalable and facile manufacturability of practical e-textile products using low cost roll-to-roll processing of large-area flexible sensor systems and can be remarkably effective in advancing the field of textiles.

This post was originally published in NC State News.