An Instrumental Place

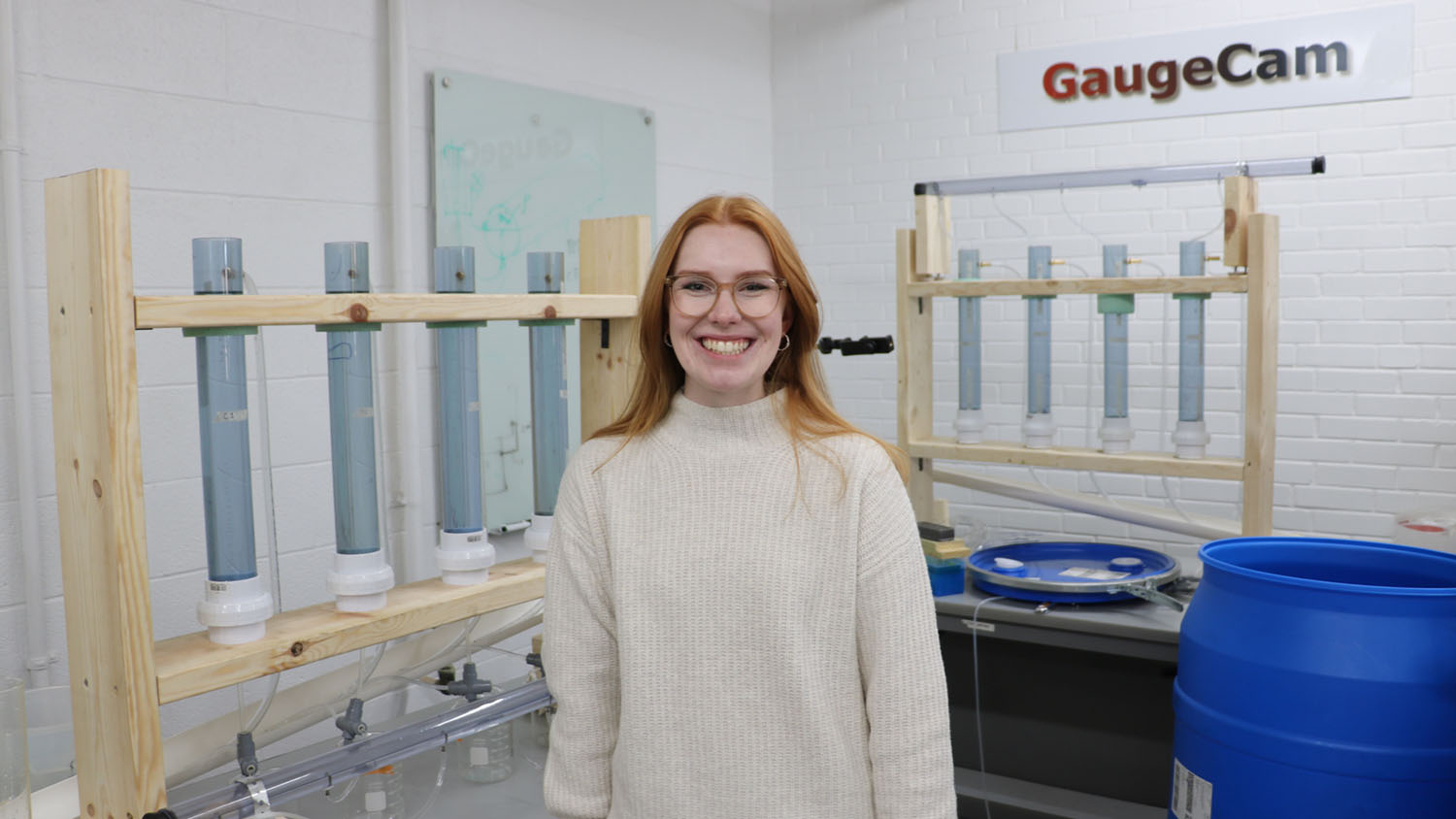

On the ground floor of Cox Hall, Chris Hewett runs the Department of Physics Instrument Shop, where he’s been building custom prototype equipment for faculty and graduate student researchers across campus for the past 19 years.

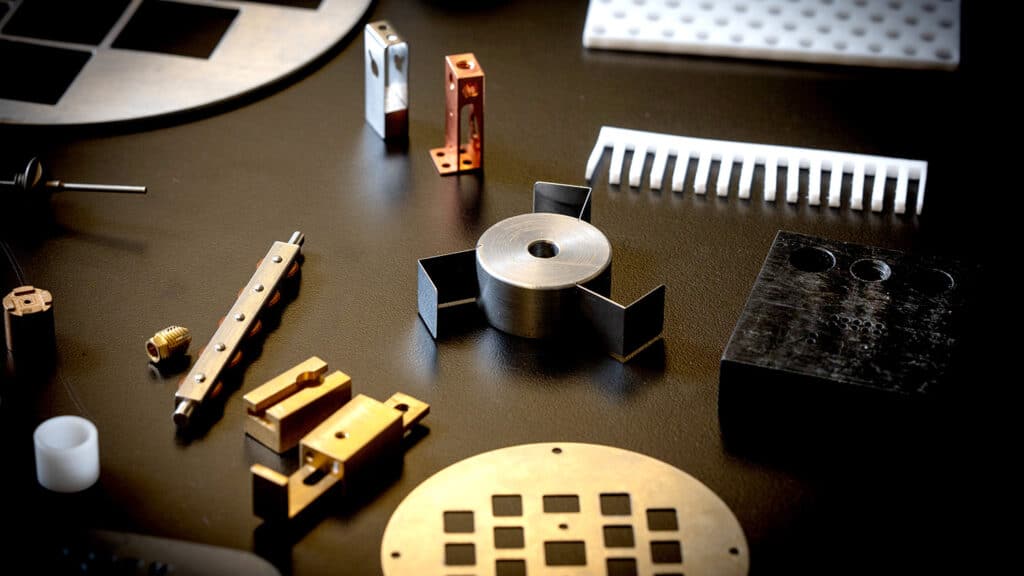

In the shop, machinists Hewett, Gary Lofton and Joe McElveen use a variety of machine tools — including lathes, drill presses, saws, manual and hydraulic shears, press brakes and Computer Numerical Control machines — to help faculty and graduate students bring their designs to life. Many of these are small gadgets that researchers use to carry out a variety of activities, like tracking how ants carry fungus from one area of the forest to another or performing microscopic brain surgery on fruit flies.

“Collectively, the three of us have nearly 100 years of machining experience to contribute to NC State’s research,” said Hewett.

Having machining services available for researchers on campus isn’t only convenient. It’s essential. Experimental physicists, for instance, often need equipment that can’t be bought anywhere.

“In experimental physics, we have to build complicated parts for our research. Without the machine shop, it would be very difficult to do our research,” said Ekaterina Korobkina, research associate in the Department of Nuclear Engineering and graduate faculty in the Department of Physics. “It’s complicated to find other machine shops that can do what we need them to do and for the price that we can afford.”

For Hewett, part of his job satisfaction comes from passing on his knowledge to help graduate students machine their own instruments — and from knowing that his own creations contribute to important research.

“Seeing all the different parts that we make, and hearing about what they do and what kind of experiments they’re used in, it’s pretty neat,” he said.

A Probe of the Early Universe

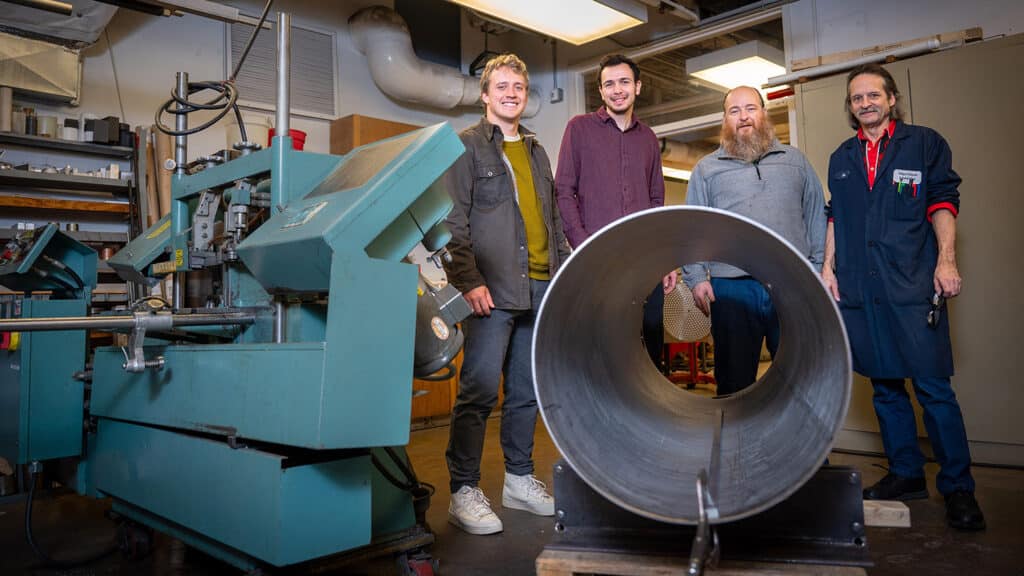

The instruments made in the shop range from small, handheld gadgets used in statistical probability tests to large structures used to explore the most confounding mysteries of the universe. One of the more ambitious projects Hewett and his team have taken on is the recently completed roundhouse, a large stainless steel cylinder where researchers will be able to store low-energy — or “ultracold” — neutrons and select their energy distribution.

For nearly a year, Hewett has been working with a number of NC State physicists — including Korobkina, physics department head Paul Huffman and doctoral students Clark Hickman and Cole Teander — to design and build the roundhouse.

The structure will be used in an experiment to better understand the origins of the universe. When the universe began, matter and antimatter collided. Antimatter has the opposite electric charge and magnetic strength and orientation as ordinary matter. In theory, if the universe had symmetry — a perfect balance between matter and antimatter — nothing would exist because matter and antimatter annihilate each other when they come into contact. Given that we live in a universe made of matter, we know this did not happen.

“There’s a fundamental asymmetry baked into the universe,” said Teander.

The researchers are studying ultracold neutrons — which move slowly enough that they can be contained by normal matter, such as stainless steel or copper — to determine the reason behind this asymmetry.

“Studying neutrons is a great probe of the early universe, because they were one of the dominant particles of the first 15 minutes of the universe,” said Teander.

“And they’re one of the simplest,” said Hickman.

Hickman and Teander have transported the roundhouse to the Los Alamos National Laboratory in New Mexico, where it will be connected to the institution’s ultracold neutron source. The structure will then act as a filter of sorts to change the energy of the neutrons.

“This device helps us understand the energy spectrum of the neutron, which is important for the interpretation of any data in the experiment,” said Korobkina.

The neutrons will then funnel into a prototype plastic storage box, where the researchers can later measure their electric dipole moment, or their electrical symmetry.

“This is a physics measurement that could shed light on why we live in a matter-dominated universe,” said Huffman.

To ensure the success of the experiment — which is part of a wider suite of research projects in collaboration with various universities and labs around the country — great care had to go into the construction of the roundhouse.

“The roundhouse needs to have high-quality machining and welding, and it needs to be kept very clean. Otherwise, you lose the neutrons,” said Korobkina. “[Hewett] has really good skills. And he likes challenges. He decided he would crawl into the tube and weld from inside.”

A Resource for All

Experimental physicists aren’t the only ones that benefit from the Department of Physics Instrument Shop. Hewett and his staff have completed work for other departments in the College of Sciences and across campus, including the departments of nuclear engineering, electrical engineering, entomology and plant pathology, as well as the Wilson College of Textiles.

The shop staff is currently building a particle deposition chamber for Nicholas Meskhidze, professor in the Department of Marine, Earth and Atmospheric Sciences (MEAS). The chamber will help Meskhidze develop new parameterizations for the dry deposition of aerosols in the atmosphere, a project he began with Markus Petters, a former NC State MEAS professor. Dry deposition takes place when a pollutant impacts a surface — such as a plant or building — and is removed from the atmosphere.

“Aerosols are really bad for your health. Long term exposure to small particles negatively affects cardiovascular and respiratory health in humans. If the particles are very small, they can go into your central nervous system and may cause all kinds of problems, like Alzheimer’s,” said Meskhidze. “They can also stay in your lungs and exacerbate pre-existing respiratory illnesses.

“The Environmental Protection Agency regulates particles with diameters of 2.5 micrometers or smaller. They regulate mass, but not number. Very small aerosols have very little mass, and so quite often they get overlooked.”

Meskhidze will be able to bring different types of aerosols into the chamber — where he can control the turbulence inside — and see how they deposit, or get attached to surfaces.

“We can also try to replicate things like deposition on leaves by planting small tree branches in the chamber,” he said. “Knowing the surface area of the leaves, we can figure out how the particles get deposited.”

It’s Meskhidze’s first time working with Hewett, but he’s been pleased with the experience so far.

“It’s very easy to work with him. Sometimes when you deal with machine shops, they ask you to give them drawings with measurements down to the millimeter. And [Hewett] isn’t like that. You tell him what you want, and he can make it,” said Meskhidze.

“I really like this, because, when it comes to the tiny little details, sometimes you don’t know because often you are building something no one has made before,” he added. “It’s not like we have an existing drawing we can replicate. Sometimes you have to play it by ear and try different things.”

These types of challenges — and the variety of projects that come into the shop — are Hewett’s favorite part of the job. And he’s just the person to take on these challenges because he’s been on the job long enough to understand researchers’ needs.

“There is some equipment you can’t buy, and that’s when you have to manufacture it,” said Meskhidze. “Having someone on campus who can do it for you, and who has this institutional knowledge of different things that would take you a lot of time to explain, I think that’s pretty beneficial.”

Gaining Machining Skills as a Graduate Student

Another passion of Hewett’s is passing on his machining knowledge to students.

“I’ve got a teacher’s heart,” he said.

The process of working with Hewett to take a piece of equipment from an idea to reality is a learning opportunity for graduate students.

“There’s a teaching piece, an educational component,” said Huffman. “When Ph.D. students are building their piece of equipment, they get feedback on what works, what doesn’t, what’s going to be too complicated to build or what could be simplified. So it’s a good back and forth.”

“The main skill I’ve learned is how to communicate with a machinist versus an engineer versus a physicist, because each one has a different expertise,” said Hickman.

For experimental physicists, knowing how to work with engineers and machinists makes for increased efficiency in the design process.

“By working with the shop, you become a better designer,” said Teander. “And hopefully skip some of the back and forth in the future.”

Aside from working with the main machine shop in Cox Hall on bigger projects, graduate physics students can also gain access to the student shop in Riddick Hall, overseen by John Thomas, the John S. Risley Distinguished Professor of Physics.

Thomas purchased machines for student use with his startup funds when he first arrived at NC State. At his previous institution, Duke University, Thomas had run a shop where he taught his students machining.

“I always found that it was very, very important, with the work I do — which is with lasers and cold atoms — to have access to a good shop that my students can actually use,” said Thomas.

Hewett teaches a course to train graduate physics students to use the machines in the student shop at Riddick, which they can use for smaller, simpler projects.

“[Hewett] is a really ideal person for interacting with the students. He’s calm. He knows how to explain everything nicely to them,” said Thomas. “They can come to me, tell me that they have taken this course, and then I know I can sign them off on various tools and give them access.”

The hands-on experience of doing their own machining and working with professional machinists pays off.

“We had a student that got a job at a company on Centennial Campus because he had fabrication and machine shop experience,” said Korobkina. “I encourage all of our students to communicate with and be familiar with the machine shop. It’s a big asset for their future.”

This post was originally published in NC State News.