Helium Recovery System at NC State

Welcome to the Molecular Education Technology and Research Innovation Center (METRIC) at North Carolina State University, a hub of cutting-edge research and technological advancement. Our state-of-the-art Helium Recovery System, funded by the NSF MRI grant (Proposal ID: 2320092), represents a significant stride in sustainable scientific practices, conserving a precious resource while supporting a wide range of multidisciplinary research activities. This system plays a vital role in supporting a diverse array of multidisciplinary research activities, bolstered by the generous support of the National Science Foundation. Discover how this innovative system is not only enhancing our research capabilities but also contributing to educational excellence and environmental responsibility.

Helium Recovery System

(Funded by NSF MRI 2320092)

METRIC Overview

The Molecular Education Technology and Research Innovation Center (METRIC) at North Carolina State University stands at the forefront of scientific research and technological development. As a core facility, METRIC provides advanced analytical services, encompassing mass spectrometry, magnetic resonance, and crystallography, catering to diverse research needs across the university and the wider Research Triangle area. With a strong commitment to both graduate and undergraduate education, METRIC integrates cutting-edge technology into research and teaching, offering hands-on experiences that are vital for developing future scientists. The center’s collaborative environment fosters interdisciplinary research, driving innovation in fields ranging from chemistry and biology to material sciences. METRIC’s dedication to excellence in research and education positions it as a leading institution in shaping the future of scientific exploration and discovery.

About Us

Team Members: Joe Barycki (METRIC Director), Jennifer Sun, Peter Thompson,

Collaborators: UNC Bimolecular Core, UNC CRITCL NMR Facility.

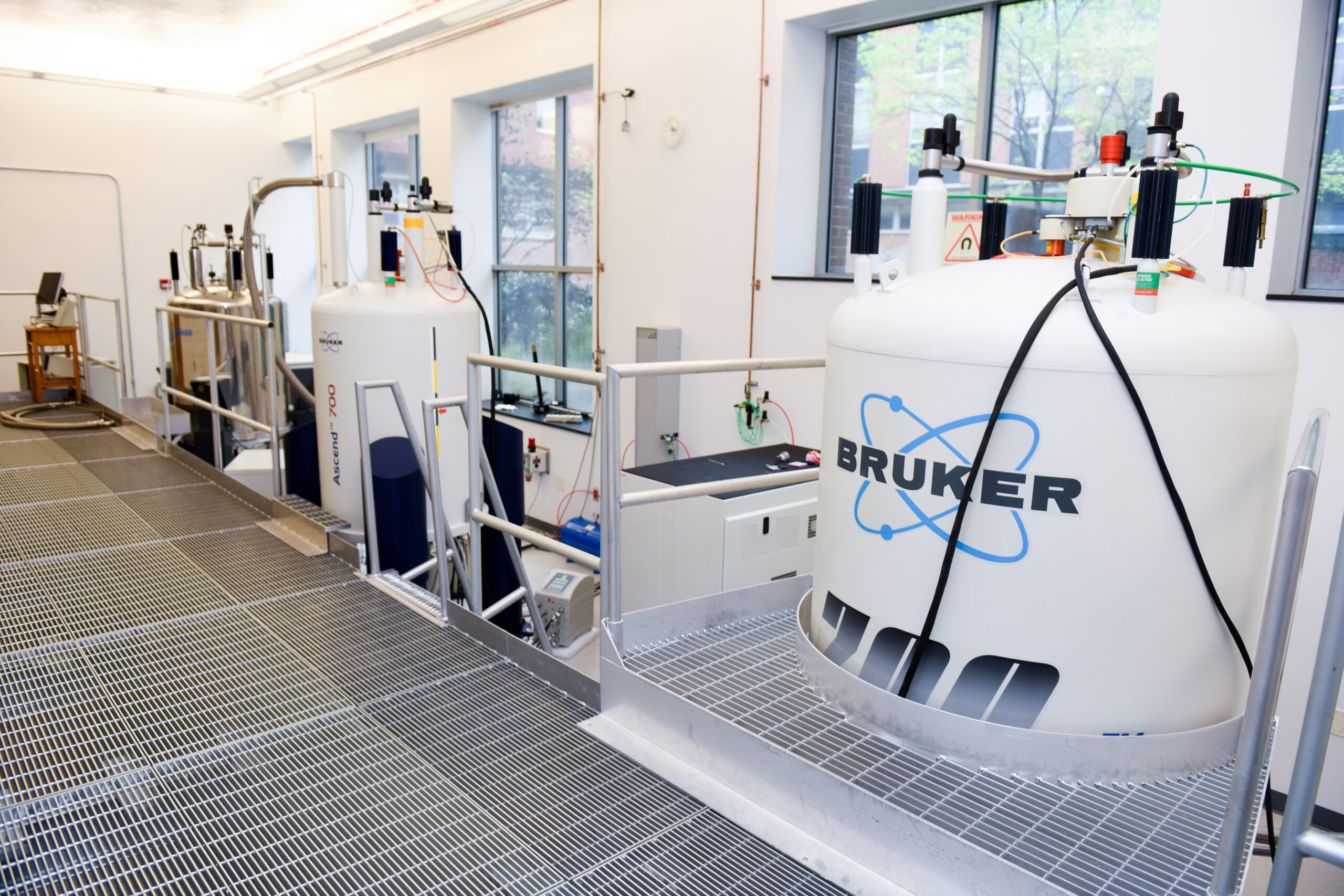

Helium Recovery System Overview

The Helium Recovery System at North Carolina State University’s METRIC is a pioneering initiative designed to optimize the use of helium, particularly in NMR spectroscopy. Strategically placed across main and satellite sites within the university, including Polk Hall, Dabney Hall, and Partners III, the system efficiently recovers and recycles helium, a crucial but limited resource in scientific research. It encompasses several NMR magnets located at these key sites, facilitating a wide range of advanced research activities. This system not only exemplifies METRIC’s commitment to sustainable practices but also ensures the continuous and cost-effective operation of NMR facilities, vital for numerous scientific investigations. Through this innovative approach, METRIC significantly contributes to reducing helium waste and enhancing the availability of this essential gas for ongoing and future research endeavors.

System Components

Liquefaction Site (Main Site – Polk Hall)

Quantum Helium Liquefier: The core of the helium recovery system. It includes a compressor, cold head, auto-control unit, and an integrated dewar. The compressor uses a chilled water system for cooling and cycles high-purity helium gas through the system. Helium gas is condensed on the cold-head’s chilled surface and accumulates in a 150L dewar. The system has a capacity to liquefy 25 liters of helium per day.

Helium Recovery Compressor : Compressor and Manages the direction of helium gas, either to the liquefier or storage tanks. This system automatically switches modes based on operational needs.

Medium Pressure Helium Storage: Consists of four metal storage tanks at the main site for holding the compressed helium before it’s purified and liquefied.

Helium Purifier: Essential for removing impurities from the helium gas stored in the medium pressure tanks and balloons. This purification is a critical step before the helium can be liquefied and reused.

Remote Satellite Recovery Sites

Helium Storage Balloons with Sensors: These are used at satellite sites for initial collection of daily boil-off helium gas. When the balloon reaches a certain volume, a sensor triggers the helium recovery process.

Helium Recovery Compressor: Located at each satellite site, these standard compressors condense the gas into high-pressure cylinders after it’s collected in the storage balloons.

Transportation: The high-pressure helium cylinders are transported to the main site for liquefaction. The liquefied helium is then transported back to the satellite sites for use, ensuring efficient recycling and minimizing losses.

System Capabilities

The Helium Recovery System at North Carolina State University’s METRIC encompasses a comprehensive process to recover various types of helium gas, primarily from NMR spectroscopy instruments:

Daily Boil-off Helium Gas:

At the main site (Polk Hall), the system recovers helium gas directly from the boil-off of three high-field NMR instruments. This gas is of high purity (>99.99%) and is continuously liquefied into a 150L stationary dewar at a maximum rate of 25 liters per day. The daily boil-off gas is expected to be recovered at a rate greater than 95%.

Helium Gas from Cryogen Refill Process:

During the magnet helium refill process, displaced helium gas is collected. This gas, along with the helium recovered from the satellite sites, is routed to the helium recovery compressor at the main site for temporary storage in medium-pressure helium tanks before liquefaction.

Helium Gas at Satellite Sites:

The satellite sites feature high-pressure helium recovery systems, including storage balloons and compressors. They collect daily boil-off helium gas as well as gas from cryogen refills.

The helium gas collected in these balloons, once reaching a certain volume, is condensed into high-pressure cylinders. Each cylinder holds approximately 12,200 L of helium gas at 1 atm, equivalent to 16 liters of liquid helium. This gas is then transported to the main site for liquefaction.

Helium gas collected at the satellite sites may contain impurities like O2, N2, H2O, and others, necessitating purification before liquefaction.Before liquefaction, the helium gas, especially from the satellite sites, undergoes purification to remove impurities such as H2O, N2, and O2. This purification step is crucial to maintain the quality and usability of the recovered helium.

Helium Gas Tracking and Maintainence

Helium Gas Flow Meter: Located at the main liquefaction site (Polk Hall), this meter tracks helium gas coming from the magnets. It records the gas from daily boil-off and during helium refills. The recorded values, including date and temperature, are logged weekly in a physical logbook.

Pressure Gauges at Satellite Sites: These gauges monitor compressed helium gas in each cylinder. Recorded data include pressure, temperature, tank ID, and position. This information is logged weekly in physical logbooks at the satellite sites, and the volume of helium gas transferred between sites is documented.

Liquid Helium Production Monitoring: The Helium liquifier digital display panel reports the status of the liquefaction system, including the volume of liquid helium in the storage dewar. The volume of liquid helium transferred to the transport dewar is determined by weighing and recorded in a logbook.

Webpage Updates: All helium recovery data is recorded in a spreadsheet, uploaded to METRIC’s shared drive, and incorporated into the Lab Management software. Monthly summaries, including total helium produced, delivered, purchased, and associated costs, are published on the NCSU METRIC website. This platform also displays the cumulative volume of helium gas collected and recovered over time.

System Maintenance

We leverage a comprehensive tracking and maintenance plan ensures efficient operation and sustainability of the Helium Recovery System, supporting METRIC’s advanced research capabilities and commitment to resource conservation.

Weekly and Monthly Checks: Key components, such as cooling oil and liquid nitrogen levels, are monitored weekly to ensure the proper functioning of the helium purifier. At the satellite sites, the high-pressure cylinder farm is harvested every month.

Routine Maintenance: The system requires regular maintenance of approximately one day every year and three days every third year. Most maintenance tasks can be performed by onsite staff.

Data Logging and System Health Monitoring: METRIC staff log operation data points and conduct daily walk-throughs of the helium recovery system. Regular logging and monitoring are crucial for maintaining the system’s health and identifying any potential issues.

Helium Recovery Track