Now Open: Hot Press Furnace Center

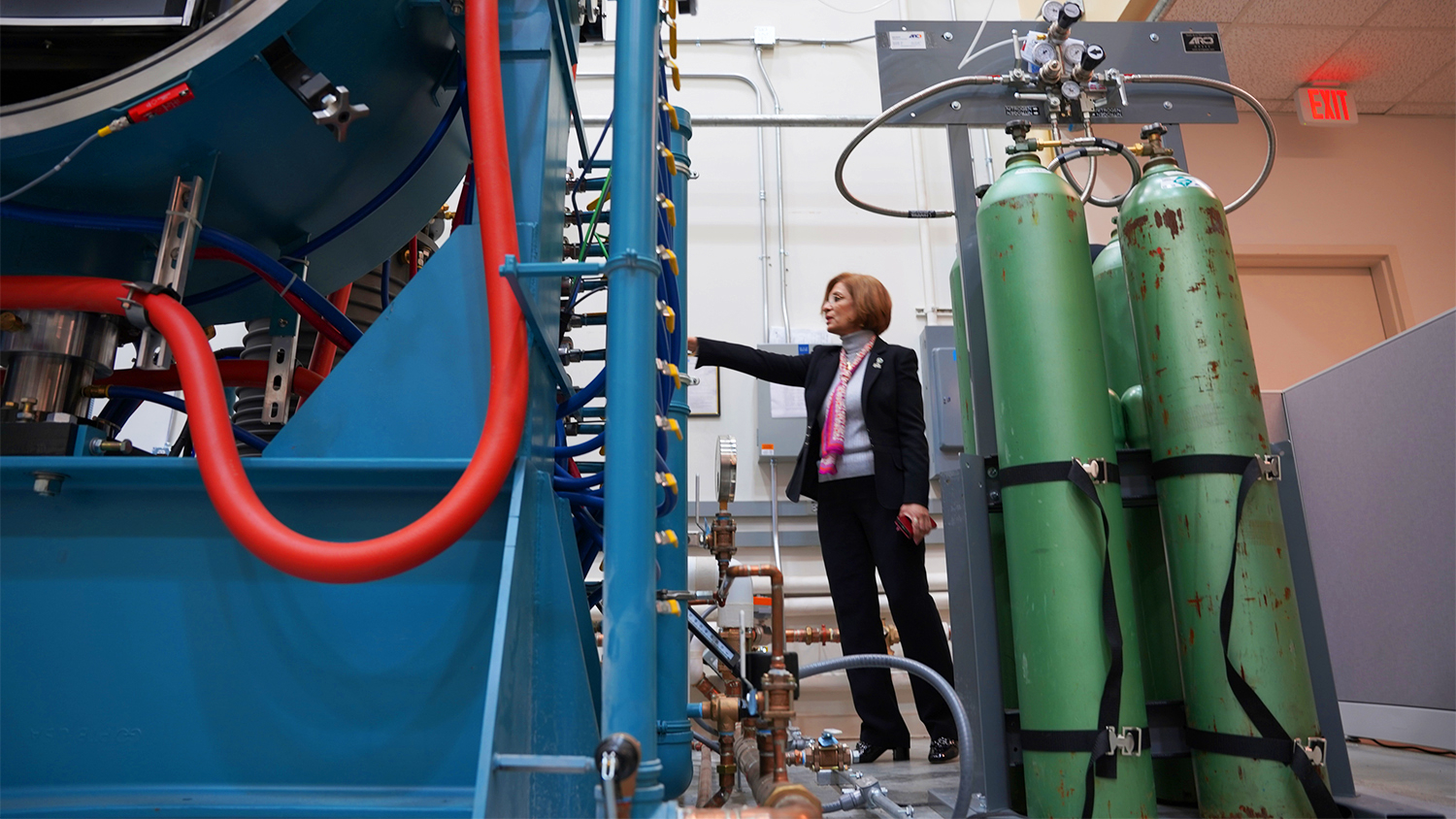

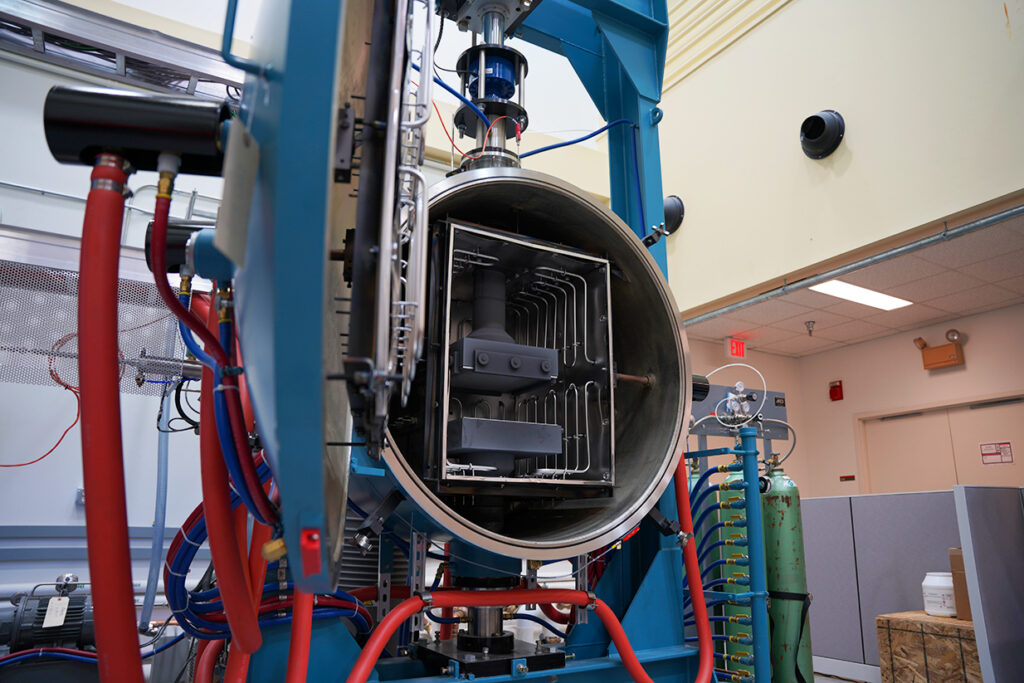

A new advanced manufacturing facility with a unique hot press system capable of reaching 2,000 degrees Celsius while applying 50 tons of pressure is now open for use on Centennial Campus.

The hot press furnace, located in Research Building II, is used to process advanced materials for structures exposed to extreme environments. Those advanced materials include metallic and ceramic matrix composites, refractory metals and ceramics, advanced sensors, advanced alloys, and composite metal foams.

The furnace has a working space area of about 14’’ by 14’’ by 18’’ – making it one of the largest in the southeast region. Researchers can submit use requests for the center on the Department of Mechanical and Aerospace Engineering’s (MAE) website.

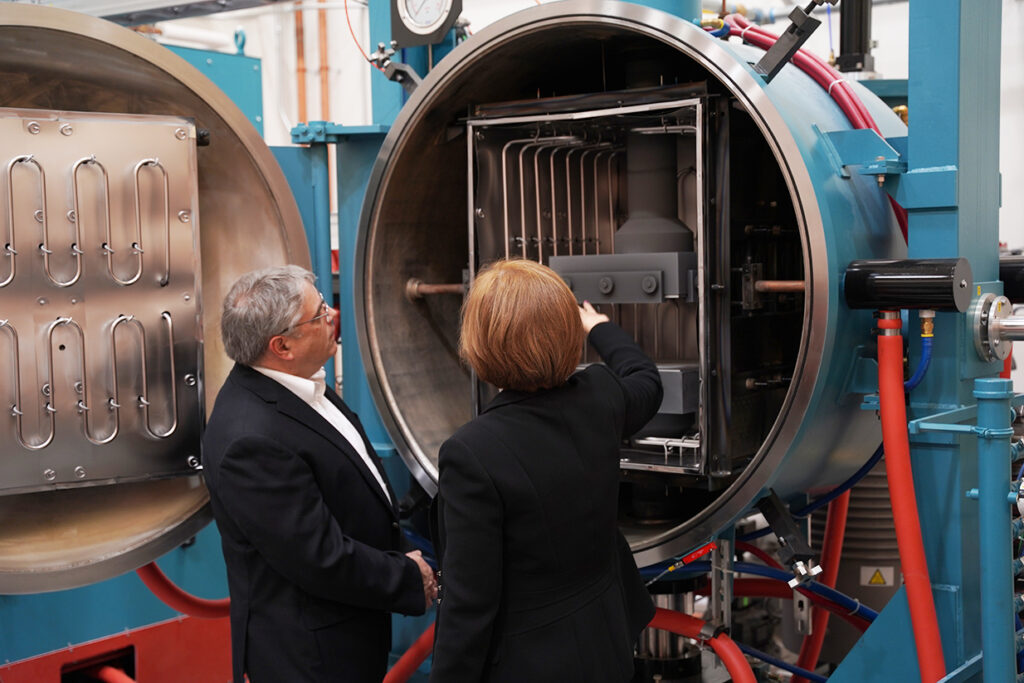

Afsaneh Rabiei, professor in the MAE department, led the efforts to bring the facility to NC State University. She invented composite metal foam, and having a hot press that can reach that high of temperature and pressure is important for her continued research.

There are many other potential users from different universities in the region and from industry who have expressed interest in the facility.

“We have people who are interested in using such a unit for manufacturing advanced materials across various colleges and departments on campus and off campus and from industries,” Rabiei said. “We have never had something in this size and capacity and capability and we are very excited to add this outstanding unit to NC State’s portfolio for manufacturing advanced materials.”

Researchers are also interested in using the facility for ceramic materials, which are difficult to melt, pour and cast. With the hot press furnace, users can start with metal or ceramic powder, bond the particles together using heat and soften the material so it can be pressed together to create a solid piece. Ceramics are a common material for sensors or insulating materials used on aircraft.

In 2020, Rabiei’s proposal was selected for funding from the National Science Foundation Major Research Instrumentation program. Due to the pandemic and supply chain shortages, she faced many challenges to order such a unique, custom-made unit. It was also difficult to find the right space on campus for housing such a large facility that requires a lot of power and cooling water.

“It was quite a project from start to finish, and I’m very proud of what we could accomplish considering all challenges,” she said.

The hot press furnace will eventually be used for educational purposes for K-12 students in addition to its research uses.

Previously, the closest hot press furnace Rabiei had access to was at NASA Langley in Virginia, but it is smaller and has a lower maximum heath than the new machine at NC State.

“I always dreamed about having such a unit here at North Carolina State University and I’m glad that through a lot of effort and a lot of people helping, we could get there,” she said. “Now it’s time to not only use it for my own research and that of my co-PIs, but also for a larger group of users whether it’s a student, faculty, a company or K-12.”

The facility officially opened with a ribbon-cutting ceremony on Nov. 14.

This post was originally published in College of Engineering News.