Portable Engine Can Power Artificial Muscles in Assistive Devices

For Immediate Release

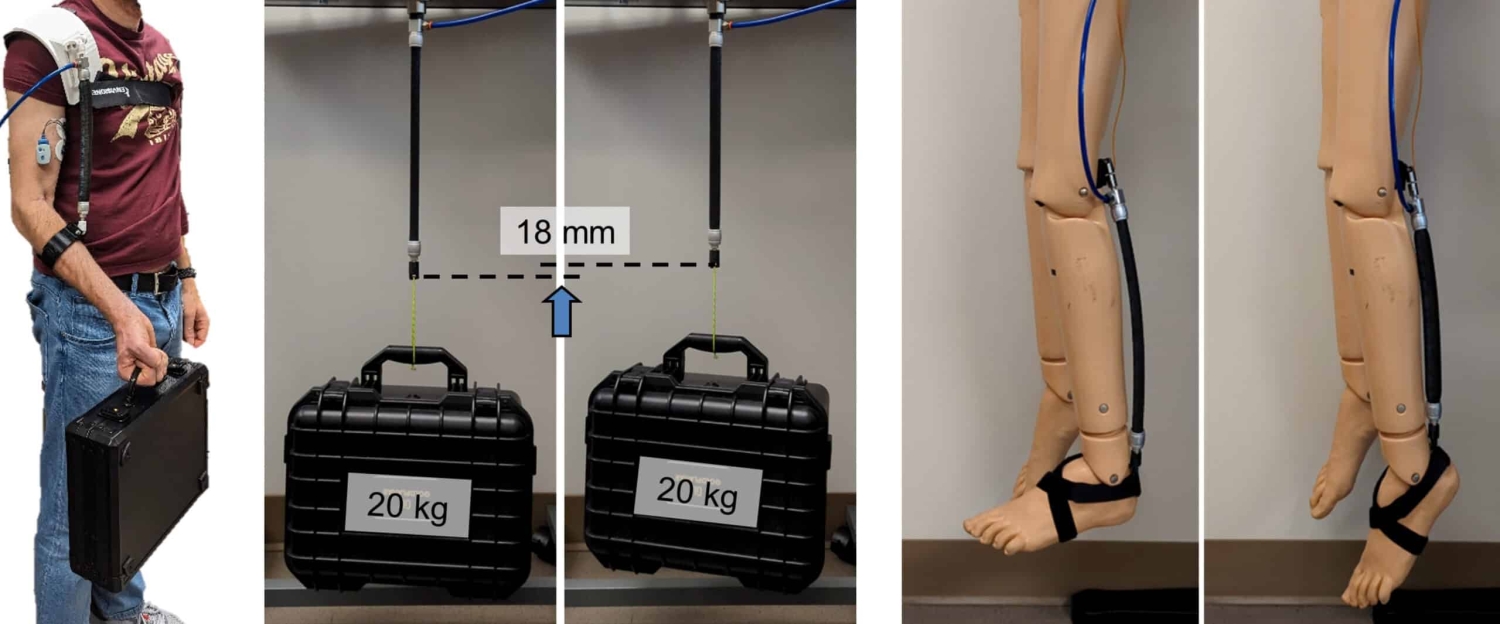

Researchers have developed a lightweight fluidic engine to power muscle-mimicking soft robots for use in assistive devices. What sets the new engine apart is its ability to generate significant force without being tethered to an external power source.

“Soft robots that are powered by fluid engines – such as hydraulic or pneumatic action – can be used to mimic the behavior of muscle in ways that rigid robots cannot,” says Hao Su, corresponding author of a paper on the work and an associate professor of mechanical and aerospace engineering at North Carolina State University. “This makes these robots particularly attractive for use in assistive devices that improve people’s ability to move their upper or lower limbs.”

However, most fluid engines are physically connected to an external power source, such as a large air compressor. That significantly limits their utility. And previous fluid engines that were not tethered to external power sources were not able to generate much force, which also limited their utility.

“Our work here addresses both of those challenges,” Su says. “Our fluidic engine is not tethered to an external source but can still generate up to 580 Newtons of force.”

The new engine works by pumping oil into and out of a chamber in a soft robot, causing the soft robot to act as an artificial muscle that is flexing and relaxing. The fluidic engine’s pump is driven by a battery-powered high-torque motor that allows it to generate significant pressure, enabling the artificial muscle to exert significant force. Video of the untethered engine can be found at https://www.youtube.com/watch?v=csVBpZIS_is.

In proof-of-concept testing, the researchers not only assessed the amount of force the new engine can generate, but how efficiently the engine converts electrical power into fluidic power.

“We found that we were able to generate an unprecedented amount of force for an untethered engine, while still keeping the weight of the fluidic engine low,” says Antonio Di Lallo, first author of the paper and a postdoctoral researcher at NC State. “And the maximum efficiency of our fluidic engine is higher than previous portable, untethered engines.”

The paper, “Untethered Fluidic Engine for High-Force Soft Wearable Robots,” is published open access in the journal Advanced Intelligent Systems. The paper was co-authored by Shuangyue Yu, a former postdoctoral researcher at NC State; Jie Yin, an associate professor of mechanical and aerospace engineering at NC State; Jonathon Slightam of Sandia National Laboratories; and Grace Gu of the University of California, Berkeley.

This work was done with support from the National Science Foundation under grants 2026622 and 1944655; the National Institute on Disability, Independent Living, and Rehabilitation Research, under grant 90DPGE0011; and Amazon Robotics.

-shipman-

Note to Editors: The study abstract follows.

“Untethered Fluidic Engine for High-Force Soft Wearable Robots”

Authors: Antonio Di Lallo, Shuangyue Yu, Jie Yin and Hao Su, North Carolina State University; Jonathon E. Slightam, Sandia National Laboratories; and Grace X. Gu, University of California, Berkeley

Published: June 13, Advanced Intelligent Systems

DOI: 10.1002/aisy.202400171

Abstract: Fluid-driven artificial muscles exhibit a behavior similar to biological muscles which makes them attractive as soft actuators for wearable assistive robots. However, state-of-the-art fluidic systems typically face challenges to meet the multifaceted needs of soft wearable robots. First, soft robots are usually constrained to tethered pressure sources or bulky configurations based on flow control valves for delivery and control of high assistive forces. Second, although some soft robots exhibit untethered operation, they are significantly limited to low force capabilities. Herein, an electrohydraulic actuation system that enables both untethered and high-force soft wearable robots is presented. This solution is achieved through a twofold design approach. First, a simplified direct-drive actuation paradigm composed of motor, gear-pump, and hydraulic artificial muscle (HAM) is proposed, which allows for a compact and lightweight (1.6?kg) valveless design. Second, a fluidic engine composed of a high-torque motor with a custom-designed gear pump is created, which is capable of generating high pressure (up to 0.75?MPa) to drive the HAM in delivering high forces (580?N). Experimental results show that the developed fluidic engine significantly outperforms state-of-the-art systems in mechanical efficiency and suggest opportunities for effective deployment in soft wearable robots for human assistance.

This post was originally published in NC State News.